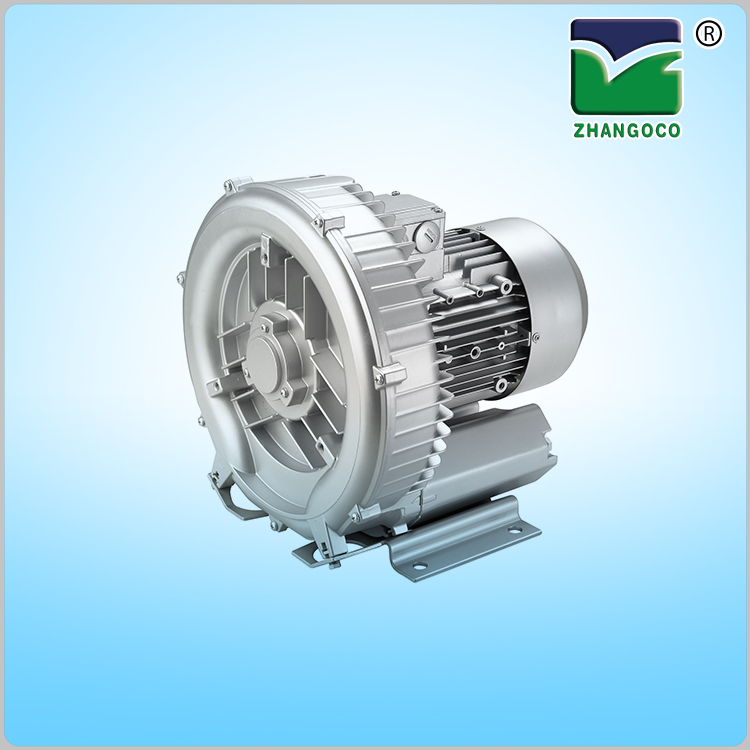

Description of the fault repair of the high pressure centrifugal fan.

Because of its high speed, the high-pressure blower has a high balance on its balance. Therefore, the company has carried out a balance test on the high-pressure blower produced, especially the impeller of the fan. The impeller of a high-pressure blower is very sensitive to the balance around it, but the slight imbalance in its heart is not very strict. In response to this feature, we can repair the fan impeller failure that is easy to occur by the following methods:

(1) If the rivet head of the high-pressure fan impeller is worn, it can be welded by welding the impeller body and the hub to return the worn rivet head to its original normal state.

(2) If the fatigue crack is easily generated at the rivet hole, the new crack can be repaired by using a new unused welding rod, but it should be noted that the impeller axis line is symmetrically centered, and the remaining welding rod of the crack is repaired. At this point, a new electrode is used to repair the rivet hole crack. The remaining electrode after welding is as long as the remaining electrode when the symmetrical rivet is repaired to ensure that the weight of the weld is equal. If there is no crack at the symmetrical rivet hole, the electrode should be welded here to offset the newly added welding weight at the symmetry rivet hole crack. According to this method of symmetrical compensation, the crack can be repaired by welding.

(3) Simple dynamic balance test on the high pressure fan impeller, the method is also very simple. After the impeller is lifted up, move it by hand to make it gently rotate. If it is not balanced, it will stop at the lowest point and will swing left and right. If there is a bias, you can spot weld on the opposite impeller, increase the weight to balance, or use the angle grinder to grind away the weld marks of the heavy impeller, and balance can be achieved, so that the high pressure blower can be repaired and normal work.

Note: In the repair process of high-pressure fan, you can not use spot welding to spot weld, leave the weld mark on the impeller, so as not to affect the balance of the high-pressure fan impeller, not only can not achieve the purpose of repair, but cause greater losses.