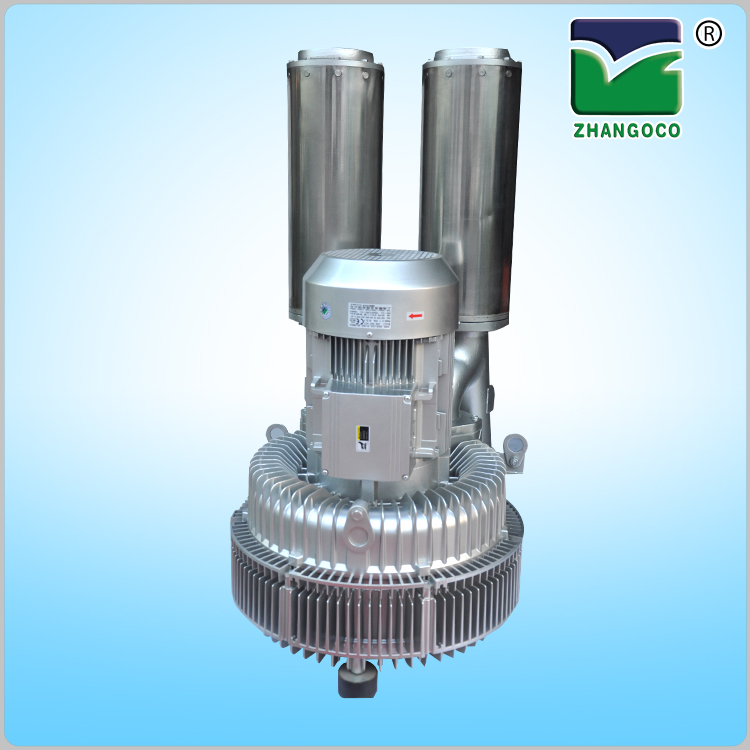

The manufacturer of the vortex blower communicates with you about the conditions under which the vortex pump can be easily maintained.

In order to extend the service life of the vortex pump and reduce the chance of equipment failure during operation, many companies attach great importance to the maintenance and maintenance of such equipment. When there is a problem that the flow rate is reduced or the noise is increased and the temperature is raised in the device, the device can be simply maintained, and only the operator needs to process the device.

When the vortex air pump has a flow reduction in operation, you can stop the equipment first, cut off the power supply, and then check whether there is something blocked in the air inlet of the equipment. If something is blocked, the flow will be reduced. After you have dealt with this problem, you can plug in the power and turn the device on to see if the device is working properly.

If the vortex air pump has a problem of excessive noise during operation, there may be some noise in the pump, and abnormal noise of the equipment caused by friction between the debris and the equipment. Or, it may be caused by the impeller being stuck. After the impeller is stuck, the impeller can be directly processed, and the device can be restored to normal. If it is processed, not only does the noise not decrease, but it becomes larger. It may be that the bearing is damaged. You can contact the manufacturer directly and replace the new one.

When the temperature of the vortex pump rises during use, first check if there is any foreign matter clogged, then open the filter, clean the debris, and finally perform a simple maintenance on the equipment.