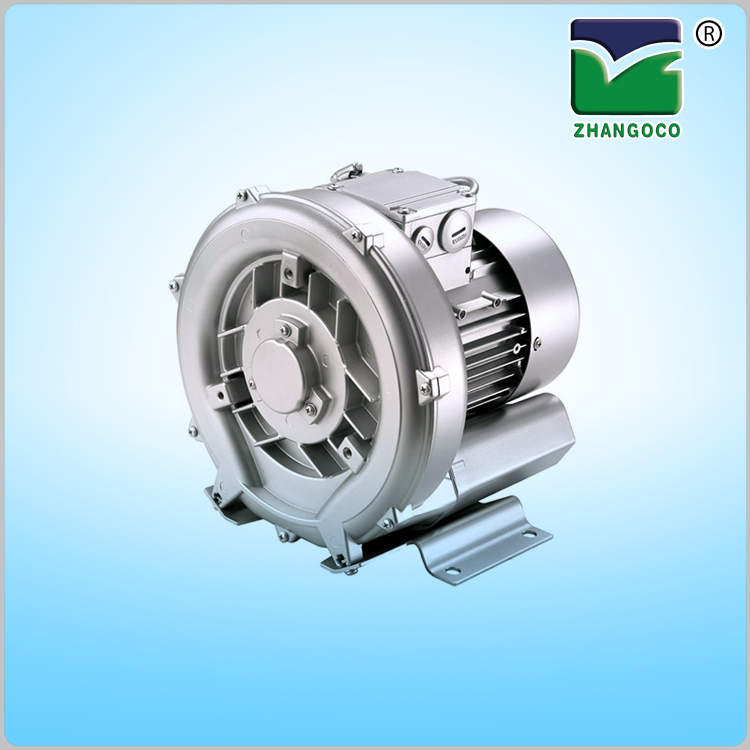

Shanghai blower manufacturers teach you how to maintain special bearings for vortex air pumps.

When maintaining the vortex air pump, pay special attention to the maintenance of the special bearings. When maintaining a special bearing, it can be carried out in a certain way and method. In the later stage, when maintaining the special bearings of the vortex air pump, the following three aspects can be operated to ensure the normal and orderly maintenance work.

1. It is necessary to check the bearing raceway of the vortex air pump. During the inspection of the equipment process, it is necessary to check whether the special bearings can operate normally. Check whether the capacity of the power supply facility is sufficient, whether the voltage can meet the operation of the equipment, check whether there are some debris in the track, and if there is any debris, it needs to be cleaned up in time. In addition, you need to check the appearance of the special bearing for damage, see how the performance of the special bearing and so on. The inspection must be done carefully and carefully.

2. Regular maintenance of the bearings of the vortex pump is required. Regular maintenance is a key factor in extending the service life of the bearing. It is best to remove the bearing during maintenance to ensure that both external and internal maintenance can be achieved.

3. See how the surrounding environment is when the vortex pump is running. To ensure that the bearing is in operation, the surrounding environment is clean and ventilated, depending on the specific use environment. Depending on the conditions of the use environment, oil is added to the bearings from time to time to ensure that it is smooth enough to avoid wear.