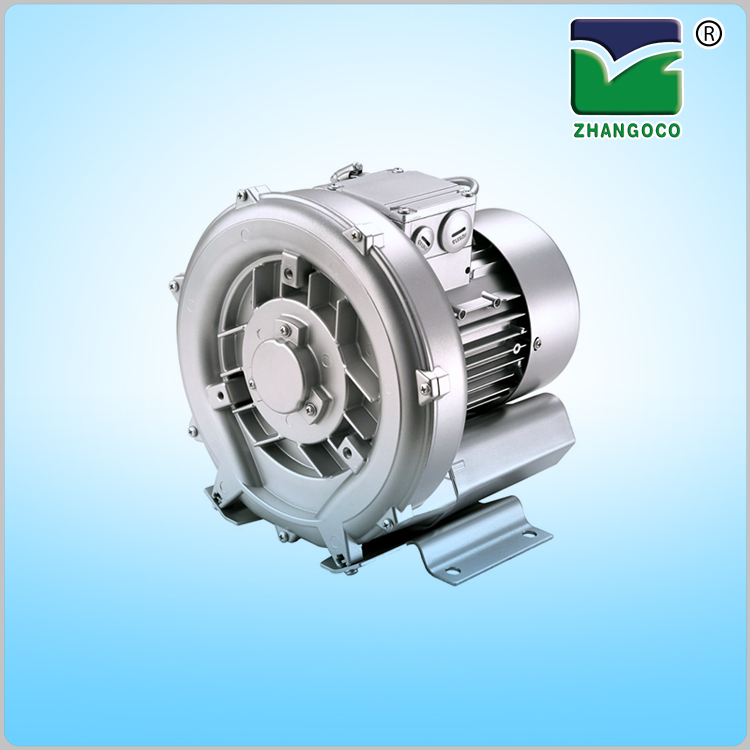

Which industries are used in high pressure centrifugal fan?

Which industries are used in high-pressure centrifugal fans? High-pressure centrifugal fans are used in: industry and agriculture, environmental protection industry, automobile industry, aquaculture, electroplating industry, industrial dust collection, printing machinery industry, machinery industry, plastics industry, etc.

High-pressure centrifugal fan, high-pressure centrifugal fan, many people think that there is not much difference between the two, in fact, wrong! Although these two are a difference of 9-19, 9-26, there is a difference, but the fan The performance is really two different.

The high-pressure centrifugal fan was upgraded on the basis of the original 9-19 high-pressure centrifugal fan. Many times, for example, the gas generator, when our pressures went up, we found that the flames in the furnace were taken away by our fans. It is.

At this time, our heat can not meet the design requirements. In response to this situation, our normal fan has been improved several times to create the requirements of satisfying both the pressure and the air volume, achieving the best of both worlds. .

The transmission mode of the high-pressure centrifugal fan is still in the two ways of A and D.

However, at the time of design, the fan shell of 9-26 is 5-6cm wider than the width of the shell of 9-19, the angle is 15° from the original, the belt is 35°, and the number of blades is still 12 pieces.

The design parameters of the high-pressure centrifugal fan are: air volume: 3215m3/h--155421m3/h; wind pressure: 3407pa--16250pa. From the above, it can be seen that the wind pressure of the fan is 1.5 times that of the traditional 9-19.

Therefore, it is generally necessary to use our 9-26 high-pressure centrifugal fan when there is enough pressure to reach the air volume.

At the beginning of the design of the fan, the manganese plate was selected as the impeller of the fan, which not only can play a good feature such as wear resistance, high temperature resistance, oxidation resistance and small loss.

From the traditional power of the fan, the design is from the 2.2KW-1000KW organic number to meet.

Generally, there is no problem in the introduction of the boiler from 1 ton to 50 tons. Can be assured of choice. The fan can also be equipped with a built-in shock absorber when designing.

Fan introduction 9-26 high pressure centrifugal fan main use:

Generally used in forging furnace, high pressure forced ventilation and can be widely used to transport materials, transport air, no corrosion is unnatural, no viscous material gas, medium temperature does not exceed 80 ° C. According to users, can be made high temperature resistant fan, For example, we often say that the stainless steel material, 304, 201, 316, 316L, etc., can also be made of FRP material, which can play an anti-corrosion, anti-corrosion and so on.

The high-pressure centrifugal fan is selected according to the size of its own boiler and the length of the connected pipe. For example, our commonly used 4 ton boiler uses 6.3A with 18.5KW fan to solve our production problems. .

The air volume and air pressure of the high-pressure centrifugal fan can be achieved. In addition, the fan needs to be equipped with a wind damper, which can freely control the air volume.

High-pressure centrifugal fans need to pay attention when installing:

The ground installed by the high-pressure centrifugal fan must be leveled. The best-good is to put it on a concrete floor separately; because the fan has a certain resonance during operation.

The bottom of the high-pressure centrifugal fan must be equipped with 4 or more rubber shock absorbers or spring shock absorbers, which can solve the vibration feeling during operation.

The high-pressure centrifugal fan must not idling during the power-on operation. It must be connected to the pipeline to start running. In the case of idling, no negative pressure will cause the voltage of our fan motor to increase, and even the motor will burn out.

The high-pressure centrifugal fan should be shut down for maintenance every 3-5 months to replace the butter inside the motor, and the impeller should be cleaned. If the impeller is found to be vibrating, disassemble it in time to make a static balance.