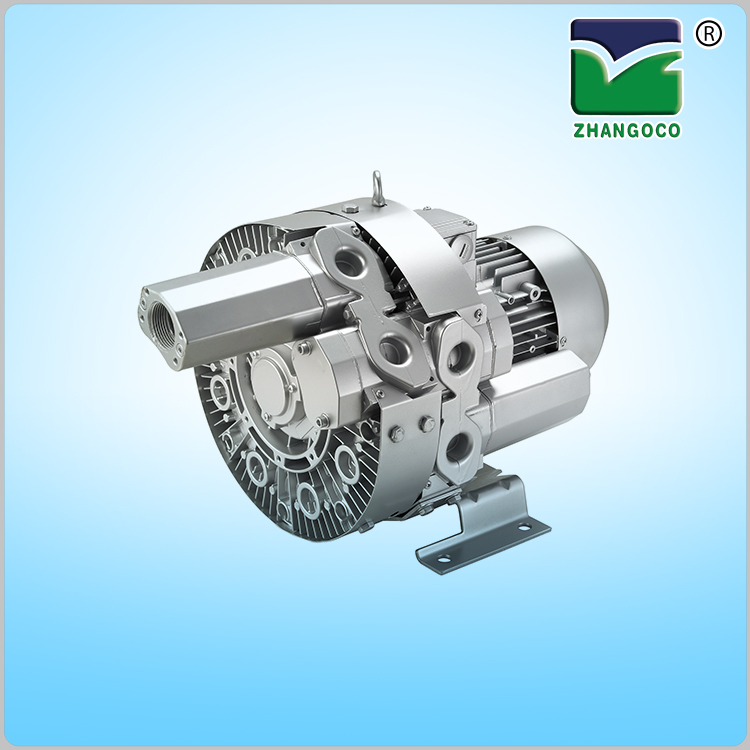

The working principle of high pressure centrifugal fan.

When the impeller rotates, due to the centrifugal force, the wind direction causes the gas to move forward and outward, thereby forming a series of spiral motions. The air between the impeller blades rotates in a spiral shape and squeezes the gas outside the pump body into the side groove (inhaled by the suction port 1). When it enters the side channel 2, the gas is compressed and then returned to the impeller blade. Speed up the rotation again. As air passes through the impeller and side slots along a spiral track, each impeller blade increases the degree of compression and acceleration, and as the rotation progresses, the kinetic energy of the gas increases, causing the gas pressure passing along the side passages to increase further. When the air reaches the junction of the side channel and the discharge flange (the side channel narrows at the outlet), the gas is squeezed out of the blade and discharged through the outlet muffler.

High pressure blower features

In general, high pressure blowers have the following characteristics:

1. It has the function of blowing and sucking, and it can be used for both air and air.

2, less oil or no oil operation, the output air is clean;

3. Compared with centrifugal fans and medium-pressure fans, the pressure is much higher, often more than ten times that of centrifugal fans.

4. If the pump body is integrally die-cast and the shock-proof mounting foot is used, its requirements for the installation base are also very low. It can even operate normally without fixing the foot. It is very convenient and saves installation costs. And installation cycle;

5. Relative to other types of fans, such as Roots blowers, the running noise is lower, the greater the power, the more obvious, 5.5KW or more will be displayed;

6, maintenance-free use; its loss parts are only two bearings, within the warranty period, basically no maintenance;

7. The mechanical wear of the high-pressure blower is very small, because there is no other mechanical contact part except the bearing, so the service life is of course very long. As long as it is under normal use conditions, there is no problem for 3 to 5 years. of. The full-air high-pressure blower even proposed a limited one-year replacement, three-year warranty value-added service;

Selection of high pressure blower

The use of high pressure blowers is very extensive because of its relatively complex selection. In general, you need to do the following two steps:

1. It is necessary to determine what function of the high pressure blower is used in the field. Whether it is sucking or blowing, find the pressure-flow curve corresponding to the high pressure blower; if the wrong curve is read, sometimes the selected product cannot be used;

2. According to the calculated pressure and flow rate, find the working curve above the working point corresponding to the pressure and flow rate on the graph; then select the high pressure blower model according to the working curve;

As long as they are different job sites, their demand for pressure and flow is different. Therefore, in order to get relatively accurate data, relevant calculations are needed. This needs to be done by a professional designer or by a professional company.

Installation precautions for high pressure blowers

1. It is necessary to use a flat washer and a spring washer to tighten the screw;

2, can use rubber buffer rubber to withstand the weight of high-pressure blowers, especially high-power high-pressure blowers, essential;

3. For some occasions where noise is required, a silencer can be added to reduce the noise (generally about 50 decibels), and the silencer is installed at the end of the air inlet duct or the air outlet duct;

4. For some occasions where the noise is very high, you can meet the noise requirements of the site according to the conditions of the machine itself, plus a layer of silencer, specifically consult the manufacturer of the high pressure blower or the professional noise control company;

5. When using silencer cotton silencer, pay attention to the distance between the high pressure blower and the cabinet, pay attention to the ventilation and heat dissipation of the high pressure blower, and pay attention to the use of rubber buffer rubber to bear the weight of the high pressure blower;

6. The inlet and outlet of the high-pressure blower are connected by pipes, and hoses should be connected to isolate the vibration.

Precautions for use of high pressure blowers

No matter which brand of high-pressure blower, it needs to be protected in two aspects: one is pressure, the other is dust, and the third is that the high-pressure blower cannot be reversed.

For pressure, the pressure relief valve is often used, which is an unloading valve. When the pressure of the high pressure blower exceeds the pressure set by the pressure relief valve, the pressure relief valve will automatically open to release the excess pressure. Protect the high pressure blower.

For dust, MF filters are often used. It is based on different use sites, often using different filter precision filter cartridges, different filter cartridges have different maintenance methods and service life, you need to ask when ordering.

In some special occasions, special protection is needed: for example, when using in a sealed environment, pay attention to ventilation and heat dissipation; when the ambient temperature (the intake air temperature is relatively high), pay more attention to ventilation and heat dissipation, or choose to allow air intake. High temperature blower with higher temperature.