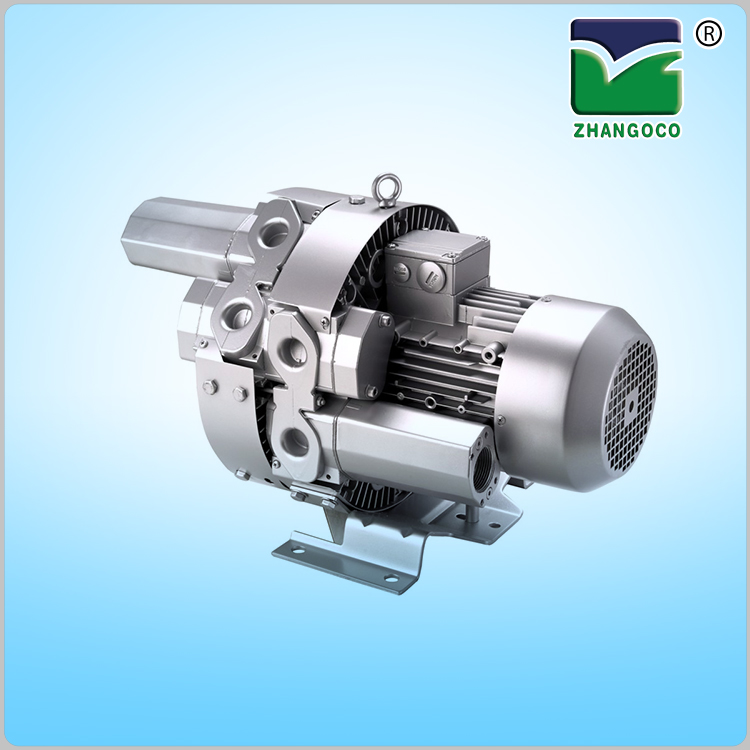

Recently, many friends have consulted us online: the high-pressure centrifugal fan blower wears, can you repair it?

We are also speechless, we are the manufacturer of the fan, not the fan repair shop.

Today, Xiaobian found some information about fan impeller maintenance on the Internet, for everyone to share: centrifugal fan

If the blades of the centrifugal fan impeller wear a large gap and the fan blades are seriously worn out, they cannot continue to operate.

If the user has an electrician or welder in the field.

It is possible to carry out some repairs without removing the impeller on site.

The specific method is as follows:

First, according to the wear situation of the on-site impeller, the cutting line is drawn on the blade, and the portion where the blade is worn and thinned is carefully cut off.

Then use a sanding machine to clean the around the incision and remove debris such as welding slag and burrs to facilitate the next welding work.

Then, according to the size of the cut blade, the blade spare parts are cut on the steel plate, and it is preferable to use the steel plate of the same material as the wind wheel for operation.

The three sides of the spare part steel plate in contact with the impeller are ground to a single bevel.

Welding can be done by cold welding, DC reverse connection, etc.

It is necessary to master the welding well.

Carefully clear the roots with an angle grinder, and repeat the above steps after confirming that there are no defects, and solder the back.

Carefully remove the coating after welding and be sure to remove it.

Before the impeller is in equilibrium, the impeller must be carefully cleaned, including the crust and ash on the impeller.

After the centrifugal fan is repaired, it runs smoothly for a period of time, and the operation rate is above 95%. The centrifugal fan is considered to be in normal operation.